Kiss cutting specialists in Tredegar and across Newport

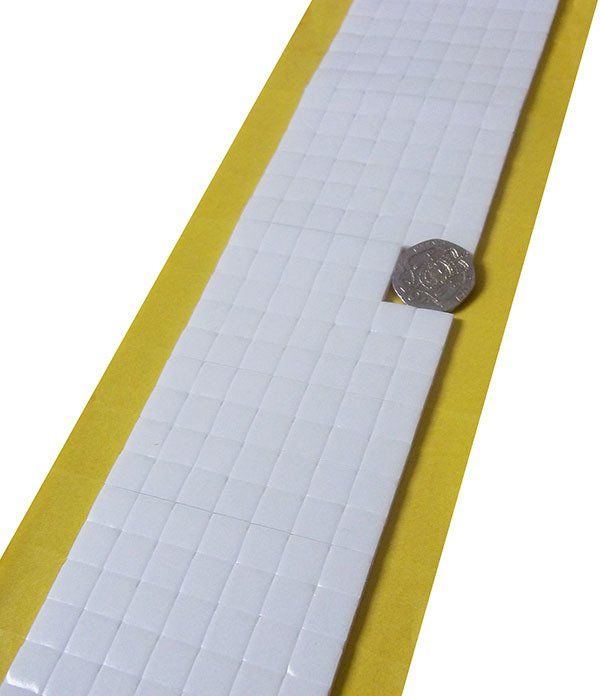

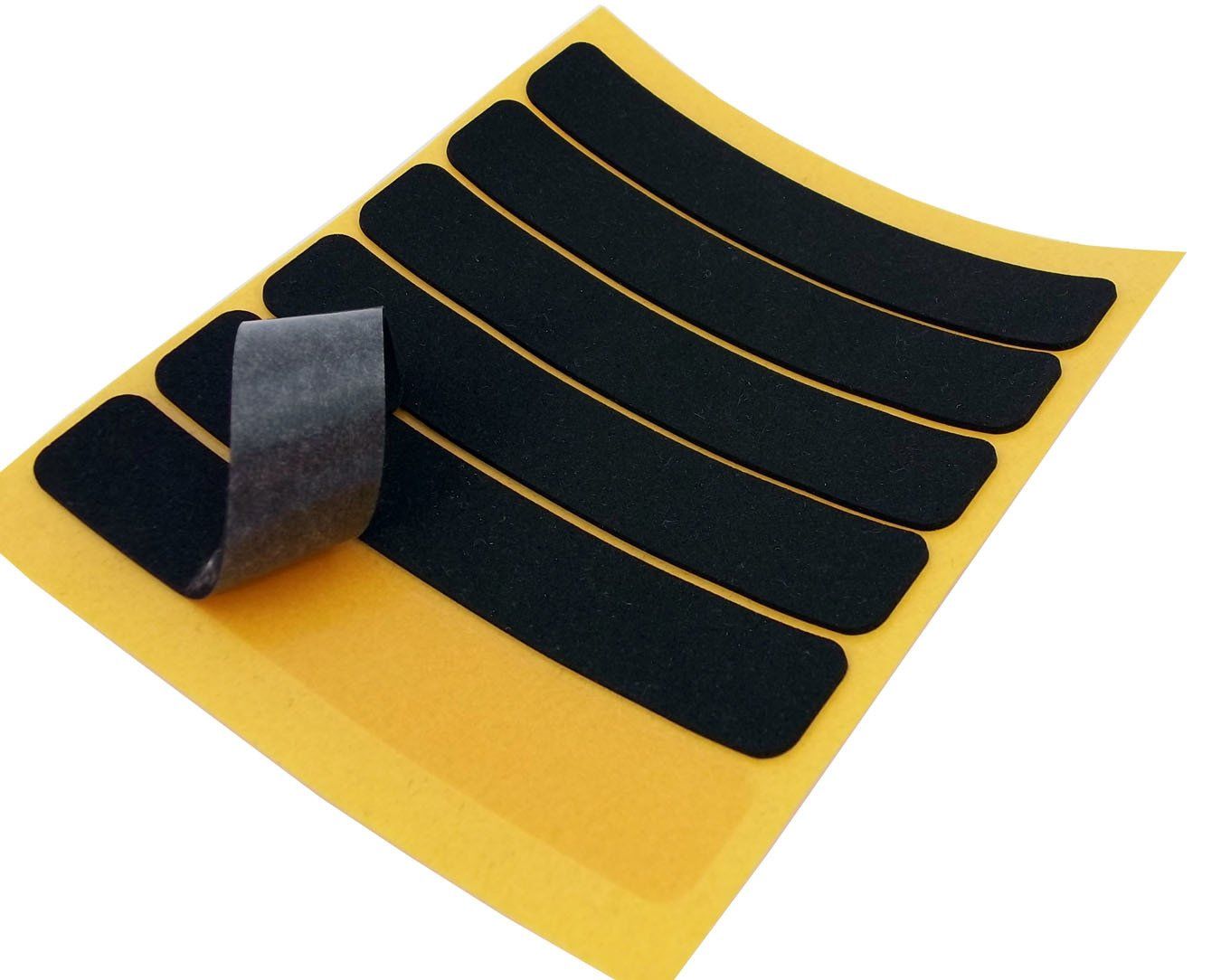

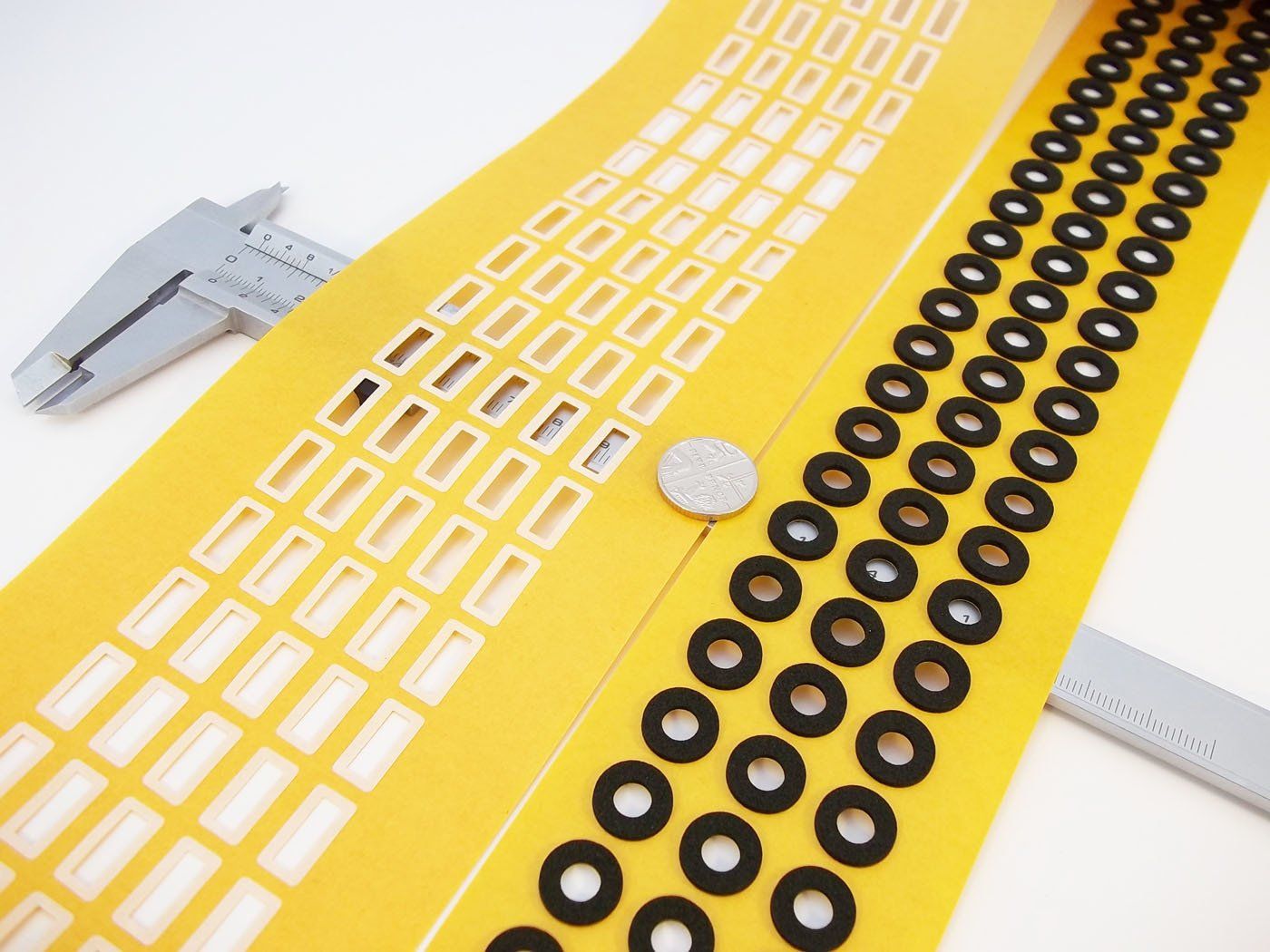

Kiss cutting is the perfect process for creating peelable products like adhesive backed gaskets and foam pads. Discuss your needs with Adhesive Backed Materials Ltd today.

Component Trays

Photo By: John Doe

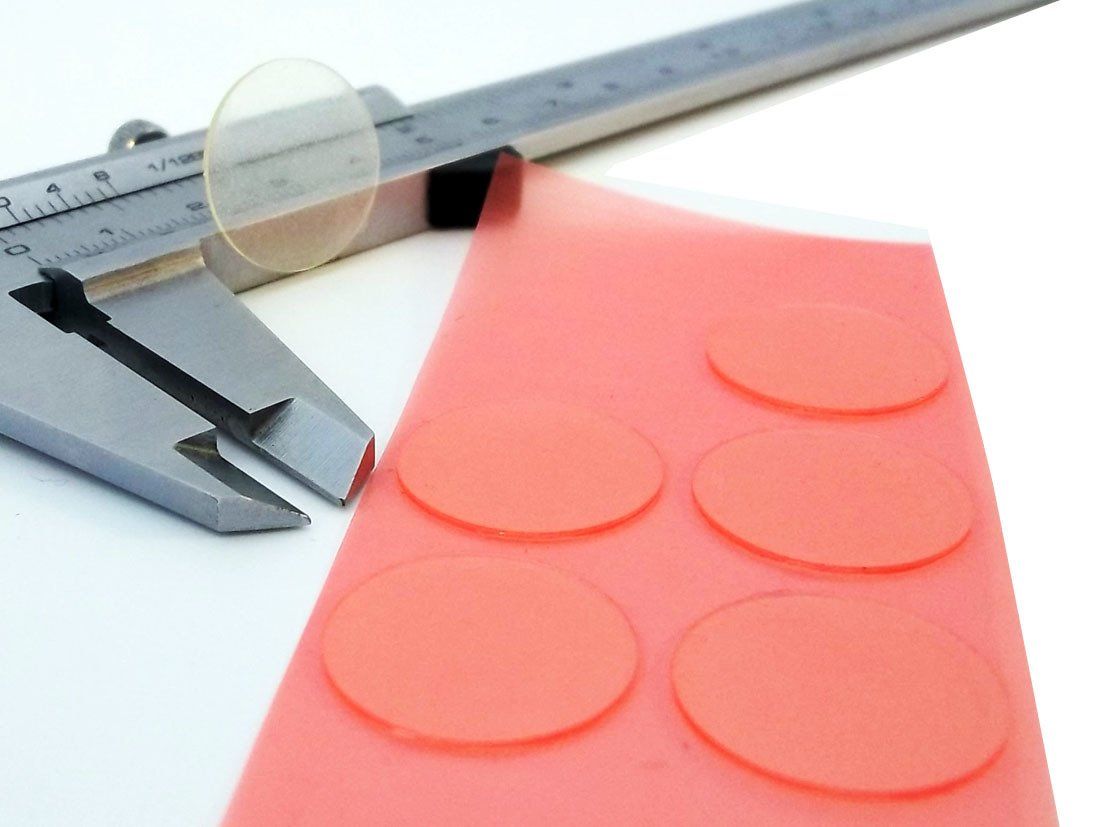

Profile/Die Cutting

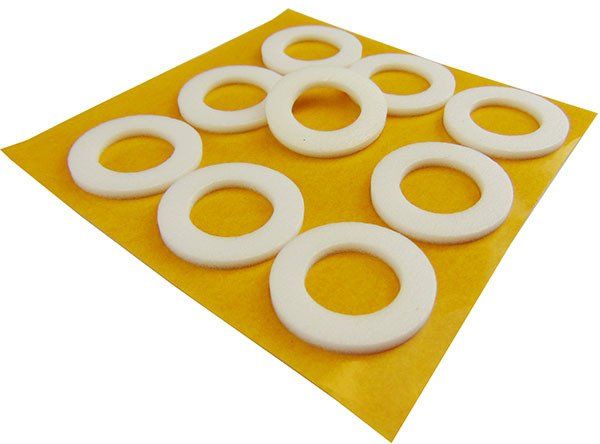

Washers

Photo By: John Doe

Material Lamination

Presentation Box Inserts

Photo by: John Doe

Adhesive Backing

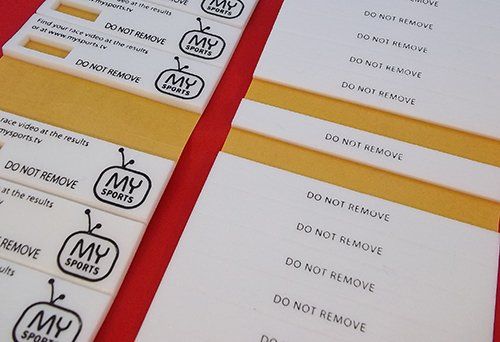

What is kiss cutting?

Kiss cutting allows you to create products where you want to cut the material layer, but not all the way through the backing layer. A common example would be stickers, which allow you to peel off a sticker whilst leaving the backing intact. It's ideal for ease of assembly and when you require specific numbers of products on a single sheet or roll.

Because you can easily remove your pre-cut items from the release paper this method can help save time and money in your assembly opperation and the cutting method is much faster than die-cutting which translates to a very cost effective product.

We can even supply most kiss cut products with waste material already removed.

We can help design and produce bespoke kiss-cut items in-house.

Kiss cutting is typically used for:

- Adhesive Backed Gaskets

- Anti-vibration pads

- Sponge rubber seals

- Profuct Feet Pads

- Foam gaskets

- Flock base protection pads

- Automotive gaskets

- Adhesive Gaskets

From materials such as:

- Polyurethane foam

- Cross linked foam

- PVC foam

- EVA Foam

- Nitrile

- Silicone

- EPDM

- Conductive Elastomers

- Felt

- Neoprene & EPDM sponge rubber

- Flock

- Leather

- Polypropylene